Temperature-sensitive extreme frozen shippers are crucial in maintaining product quality by keeping goods at an extremely low temperature. Known for their exceptional performance, Extreme Frozen Shippers are just the right choice because they ensure the needed low temperatures. This may change your view on transport as these shippers are designed not only for big companies but also smaller ones, offering a variety of sizes. With them, you can feel assured your products will arrive without quality loss.

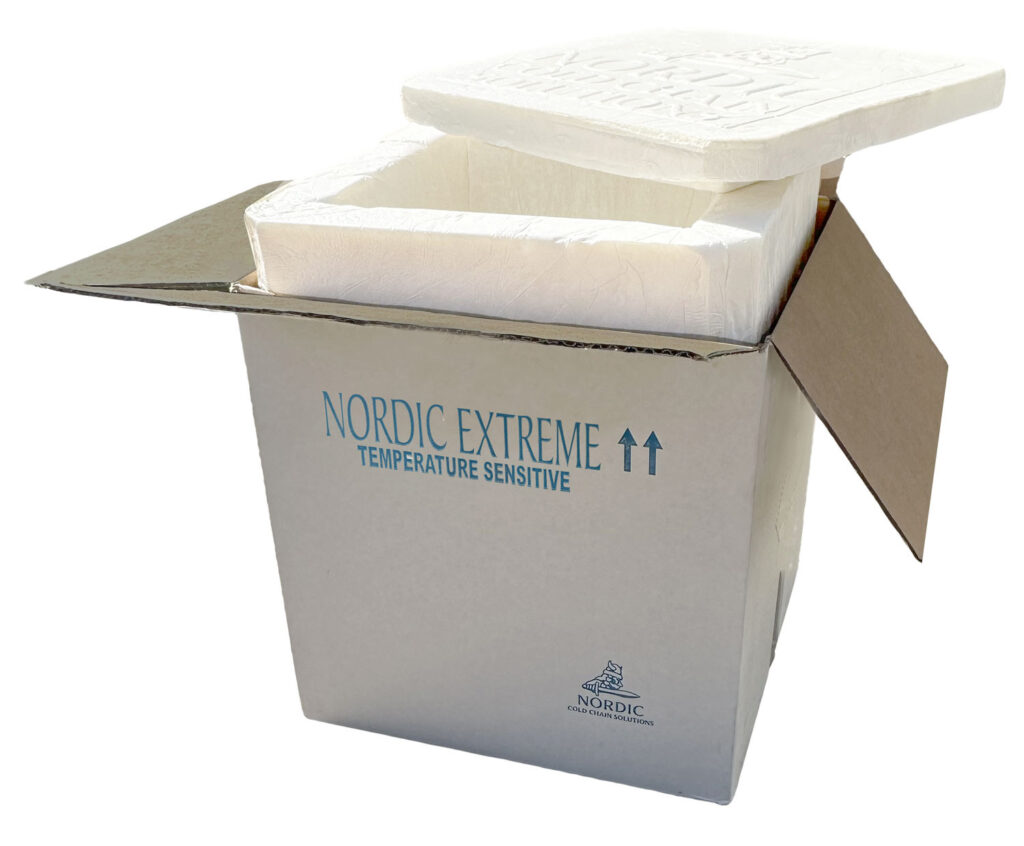

The temperature-sensitive Extreme Frozen Shippers are specifically designed to safely and securely ship temperature-sensitive products, such as pharmaceuticals, chemicals, biologics, and food. These shippers consist of a two-part design – an expanded polyurethane box that provides temperature control for sensitive products, and a corrugated exterior box for added protection during shipping. To transport your perishable goods, simply place them inside the polyurethane box, ensuring they are insulated from external temperatures, and then securely seal the shipping package for safe transportation.

Top Choice for Temperature-Sensitive Extreme Frozen Shipper

The transportation of temperature-sensitive goods in a frozen state demands precision and reliability. Extreme Frozen Shippers are specifically engineered to maintain the desired low temperatures essential for transporting perishable items.

What sets Extreme Frozen Shippers apart is their unwavering commitment to quality and efficiency. These shippers are not just any boxes with ice packs inside; they are carefully engineered solutions that have been tested and proven to maintain consistent frozen temperatures throughout the journey. This assurance is indispensable when handling delicate cargo such as vaccines, biologics, or certain food items where maintaining the cold chain is crucial.

Consider a scenario where a pharmaceutical company needs to transport a new batch of life-saving vaccines across the country. The temperatures need to remain consistently and reliably frozen throughout this journey, often lasting several days. Using our Extreme Frozen Shippers provides the peace of mind that the vaccines will arrive at their destination in optimal condition, ready to be administered without any compromise on their effectiveness.

In summary, Extreme Frozen Shippers are distinguished by their precision engineering, dedication to quality, and versatile options that make them the top choice for transporting temperature-sensitive extreme frozen goods.

With the foundation laid on the importance of maintaining frozen temperatures during transit, we now shift our focus to delve into the crucial aspects of cold chain transport and temperature monitoring.

Cold Chain Transport and Temperature Monitoring

Cold chain transport is like a carefully choreographed dance, ensuring that temperature-sensitive products are safely moved from point A to point B without compromising their quality and integrity, especially crucial for perishable goods. Maintaining specific temperature conditions is paramount to prevent spoilage and maintain freshness.

The key element in this delicate process is temperature monitoring. Advanced temperature monitoring systems, such as data loggers and real-time trackers, are integral to frozen shippers. These systems not only measure the temperature inside the shipping container but also provide critical insights into humidity levels, light exposure, and physical shocks or vibrations during transit.

Let’s use an analogy to understand the importance of temperature monitoring. Imagine transporting a sensitive instrument that can be damaged if exposed to extreme temperatures or jostled too much. Just as you’d track every move it makes, these temperature monitoring systems do the same for perishable goods—in real time and over long distances.

Data Loggers: The Silent Witnesses of Temperature Conditions

Data loggers continuously record temperature readings at regular intervals throughout the journey. These precise records provide a comprehensive overview of how the goods were handled and whether they remained within the required temperature range.

Imagine unpacking a shipment upon arrival, only to find that the goods have been compromised due to an unnoticed temperature fluctuation during transit. With data loggers in place, you have an accurate account of the temperature conditions at every stage of the journey, much like collecting detailed evidence that tells you exactly what happened every step of the way.

Real-Time Trackers: Keeping a Watchful Eye

Real-time trackers provide live updates on the location and environmental conditions of the shipment, offering immediate visibility into any deviations from prescribed temperature ranges.

Suppose you’re transporting pharmaceutical products that require strict temperature control. With real-time trackers in place, any unexpected fluctuations in temperature will trigger immediate alerts, prompting swift corrective measures to maintain the product’s integrity.

In essence, cold chain transport operates as a finely-tuned orchestra where temperature monitoring systems act as vigilant conductors, ensuring that perishable goods remain unscathed and pristine throughout their journey.

This meticulous oversight is just one aspect of maintaining cold chain integrity. Now, let’s delve into the security features and insulated design elements essential for preserving perishable products within frozen shippers.

Security and Insulated Features of Frozen Shippers

Ensuring that temperature-sensitive products remain frozen during transit is absolutely critical. Extreme Frozen Shippers have been designed to provide the utmost security and insulation for these products. They comprise a two-part design consisting of an expanded polyurethane box for precise temperature control and a corrugated exterior box for added protection. This combination not only ensures the products are safeguarded against external factors but also maintains their frozen state for 1-to-3-day shipments, even under extreme conditions.

The use of expanded polyurethane for the inner box is crucial due to its exceptional thermal insulating properties. This material efficiently traps cold air inside the box, preventing any heat from penetrating in. The result is a stable internal environment that keeps the products at the required freezing temperatures throughout the duration of transit.

Furthermore, the corrugated exterior box plays a significant role in providing an additional layer of protection. This external box acts as a shield against physical impacts and provides structural integrity to the entire shipment, ensuring that the internal polyurethane box remains intact and functional.

Security Features

Aside from insulation, security features are also paramount in maintaining the integrity of temperature-sensitive goods during transportation. Nordic Extreme Frozen Shippers incorporate tamper-evident seals to guarantee that the contents remain untouched and undisturbed throughout the journey. These seals serve as a visible indicator to all stakeholders involved, ensuring that any unauthorized access can be immediately identified.

Moreover, the design of these shippers takes into consideration the potential hazards associated with external elements. Heavy-duty construction and robust locking mechanisms are incorporated to protect against environmental factors, such as moisture ingress or physical damage, which could compromise the effectiveness of the insulation and jeopardize the frozen state of the products.

Enhanced Insulation

It’s important to highlight that the innovations in insulation technology play a critical role in safeguarding perishable goods. The efficiency of insulation directly impacts the ability to maintain consistent low temperatures during transit. With Extreme Frozen Shippers, this level of insulation has been maximized to ensure that even under extreme conditions, such as prolonged exposure to ambient heat or fluctuating outdoor temperatures, the internal environment remains unaffected and preserves the integrity of the products.

Applying these advanced security and insulated features offers peace of mind to suppliers and recipients alike, knowing that their temperature-sensitive goods are not only well-protected but also remain consistently frozen throughout their entire journey, regardless of external challenges.

Understanding how these security and insulated features work provides valuable insight into the meticulous measures taken to uphold cold chain integrity.

Alternative Solutions for Frozen Shipments

When it comes to shipping perishable goods, a variety of alternative solutions can help maintain the desired temperature during transit. While commercial frozen shippers are widely used, some situations may call for alternative methods such as dry ice or gel packs. These alternatives offer flexibility and options for cases where traditional frozen shippers may not be accessible or suitable.

Dry Ice: Dry ice is a commonly used method for keeping items frozen during transit. It is the solid form of carbon dioxide and sublimates (changes directly from a solid to a gas) at a very low temperature. This makes it well-suited for maintaining extremely cold temperatures. However, it’s important to note that dry ice does have limitations in terms of maintaining precise temperature control over an extended period. Additionally, it requires careful handling and ventilation due to its sublimation process.

For instance, if you’re shipping temperature-sensitive medical supplies or biological samples where strict temperature control is critical, using dry ice may pose challenges in ensuring consistent and regulated cooling throughout the entire shipping duration.

Gel Packs: Gel packs are another effective alternative to dry ice. They consist of a gel-like substance that freezes at lower temperatures than water, allowing them to maintain cold temperatures. Gel packs offer the advantage of being reusable, making them an eco-friendly choice. However, proper distribution of gel packs within the packaging is crucial to ensure uniform cooling and prevent potential temperature fluctuations during transit.

It’s evident that while these alternative solutions provide options for maintaining the desired temperature during transit, they also come with their own set of considerations and limitations in terms of precise temperature control and duration.

As we consider the various aspects of shipping perishable goods without traditional frozen shippers, let’s explore the crucial factors to keep in mind when selecting an appropriate alternative for maintaining cold chain integrity.

Considerations for Selecting a Frozen Shipper

Selecting the right frozen shipper for your perishable goods can feel overwhelming, but it’s crucial to make an informed decision. Several factors play a significant role in determining which frozen shipper is best suited for your specific needs.

First and foremost, you need to consider the required temperature range for your shipment. Different goods have different temperature requirements, and it’s essential to ensure that the selected shipper can maintain the necessary temperature range throughout the entire journey. For example, biological materials may require ultra-low temperatures to remain viable, while some food products might need to be kept at a steady freezing point.

Next, you should take into account the duration of transportation. Are you shipping from one state to another within the same country? Or are you sending goods across several international borders? The longer the transportation time, the more critical it is to select a shipper that can maintain stable temperatures for an extended period.

The payload size is also an important consideration. Are you shipping small, individual samples or large quantities of perishable items? The size and weight of your payload will determine the type and size of the frozen shipper you’ll need.

For instance, if you’re sending a small number of delicate pharmaceuticals, a compact and lightweight frozen shipper with precise temperature control might be more appropriate. On the other hand, larger payloads such as food orders or medical supplies may necessitate a larger, sturdier container with ample insulation.

Selecting a frozen shipper is akin to choosing the right vehicle for a long road trip. You wouldn’t pick a compact car for transporting furniture across the country, just as you wouldn’t opt for a massive moving truck for a short grocery run.

Finally, it’s imperative to be aware of any specific regulations or guidelines governing the shipment of temperature-sensitive goods. Different countries and regions have varying rules regarding the transportation of perishable items, and failure to comply with these regulations could result in delays or even seizure of your goods.

In summary, understanding and carefully considering these crucial factors—required temperature range, duration of transportation, payload size, and specific regulations—empower you to make an informed decision when selecting a frozen shipper for your temperature-sensitive goods. These considerations form the foundation upon which Extreme Frozen Shippers are designed to meet, ensuring optimal cold chain integrity for your perishable items.

When ensuring the integrity of your cold chain becomes paramount, comprehensive maintenance and handling procedures take center stage. Let’s now explore the extensive guide for maintaining and handling frozen shippers.

Guide for Maintenance and Handling of Frozen Shippers

Maintaining and handling frozen shippers is not just about taking care of a box; it’s about ensuring the safe arrival of perishable goods at the correct temperature. Proper upkeep and handling extend beyond following a checklist – it involves being aware of the conditions that might compromise the integrity of the cold chain during transit.

When it comes to maintenance, it’s essential to regularly inspect the shippers for any signs of wear or damage. Look for cracks, dents, or punctures that could compromise the insulation. If any issues are identified, prompt repair or replacement is crucial to prevent temperature excursions during shipping. Proper cleaning is also vital, as remnants from previous shipments can impact temperature control.

Adhering to manufacturer guidelines is imperative. These guidelines provide valuable information on the optimal conditions for storing and using frozen shippers. It’s important to familiarize yourself with these recommendations to maintain their performance and integrity.

Comprehensive Guide for Maintenance:

| Maintenance Task | Why It’s Important |

|---|---|

| Regular Inspection | Identify signs of wear or damage |

| Thorough Cleaning | Remove residues that hinder insulation |

| Adherence to Guidelines | Follow best practices for optimal performance |

Handling frozen shippers requires a delicate touch. Rough treatment can lead to compromised insulation or structural damage, affecting their ability to maintain temperature. During loading and unloading, it’s crucial to handle them carefully to avoid any potential impact or mishandling.

In addition, consider the environment in which the shippers are stored before use. Extreme temperatures can affect their ability to maintain the necessary temperature range for perishable goods. Ensure they are stored in an appropriate environment prior to use, as extreme temperatures can compromise their thermal performance.

Remember that even minor mishaps can have major consequences when it comes to preserving perishable goods during transit. Following these maintenance practices ensures that frozen shippers consistently perform at their best, protecting your valuable cargo throughout its journey.

Proper maintenance and handling are not just routine tasks – they are critical components in upholding the integrity of the cold chain and ensuring that perishable goods reach their destination in optimal condition.

With a firm grasp on maintaining and handling frozen shippers to uphold the cold chain’s integrity, we now shift our focus to examining the diverse array of sizes and designs available in frozen shippers. This exploration will offer insights into matching specific needs with suitable shipper options, ensuring a seamless cold chain process.

Diversity in Sizes and Designs of Frozen Shippers

Extreme Frozen Shippers understand that one size does not fit all. When it comes to shipping temperature-sensitive goods, having a variety of sizes and designs can make all the difference. Some products may need extra insulation, while others might require a smaller, more compact package. Extreme Frozen Shippers cater to these diverse needs by offering an array of options.

So, what does this mean for you as a shipper or receiver of perishable goods? It means that you have the flexibility to choose the most suitable frozen shipper based on the specific needs of your products. If you’re transporting a large quantity of perishable items, you can select a larger frozen shipper with ample space for insulation. On the other hand, if you’re dealing with smaller shipments, you can opt for a more compact design that still maintains the necessary temperature conditions.

For instance, if you’re shipping delicate seafood that requires precise temperature control, having access to different sizes and designs can ensure that your products arrive as fresh as when they were dispatched. In contrast, flowers or pharmaceuticals may have different temperature and space requirements.

Additionally, the availability of various sizes allows shippers and receivers to minimize wastage. There’s no need to use a large frozen shipper for a small payload or vice versa. This level of customization enables optimum use of space and resources.

In essence, the diversity in sizes and designs offered by Extreme Frozen Shippers serves as an assurance that your perishable cargo is in the best possible hands during transportation.

With such tailored options available, it’s clear how important it is to consider the specific needs of your temperature-sensitive products when choosing a frozen shipper.

The range of options provided by Extreme Frozen Shippers reflects a commitment to ensuring the integrity of perishable goods in transit. It’s wise to weigh these factors carefully before making a selection.