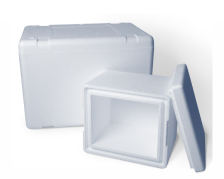

Purchase molded EPS shipping coolers here from our Chicopee, Massachusetts location, often known as Styrofoam coolers, offer a great way to keep perishable items at the right temperature. They are light in weight yet provide steady thermal insulation to safeguard the contents from shifts in temperature.

Molded EPS shipping coolers offer exceptional insulation, durability, and lightweight construction, making them ideal for protecting temperature-sensitive products during transit.

These coolers provide reliable thermal protection, reduce product loss, and can be custom-designed to fit specific shipping needs.

What are Molded EPS Shipping Coolers?

When you hear “molded EPS shipping coolers,” think of a reliable, protective cocoon for your perishable goods. These coolers act as guardians, ensuring that items maintain the right temperature and reach their destination as fresh as when they started their journey. Often referred to as expanded polystyrene (EPS) coolers or even Styrofoam coolers, they all serve to maintain stable temperatures during shipping.

The beauty of these coolers lies in their clever composition. Expanded polystyrene (EPS) is a lightweight material with remarkable thermal insulation properties. Comprising tiny air pockets that slow down the transfer of heat, it effectively maintains the internal temperature and shields the contents from external environmental changes during transit. This feature is especially crucial for items like pharmaceuticals, food, and other sensitive products that require specific temperature conditions to remain intact and viable.

The ability of molded EPS shipping coolers to combat temperature fluctuations makes them an indispensable asset in various industries. From pharmaceutical companies to food distributors, these coolers play a critical role in ensuring that perishable items reach their destination unscathed.

The Role of Temperature Maintenance in Packaging

When shipping perishable items, maintaining the right temperature throughout transit is crucial for keeping goods fresh and unspoiled upon arrival. Whether it’s pharmaceuticals, food, or beverages, changes in temperature can have a significant impact on these products.

For example, consider shipping a batch of temperature-sensitive medicines used to save lives. If these medications are exposed to fluctuating temperatures during transit, their effectiveness could be compromised, impacting patients who rely on them. Similarly, for the food and beverage sector, maintaining the quality and safety of products is essential to prevent spoilage and uphold consumer trust.

This is where molded EPS coolers play a vital role. The exceptional insulation properties of EPS (expanded polystyrene) are well-suited for providing a consistent temperature environment needed to safeguard perishable items during transit.

EPS is an excellent insulator due to its low thermal conductivity and ability to trap air within its structure. This results in an effective barrier against external temperature fluctuations, ensuring that the interior of the cooler remains at the desired temperature for an extended period.

For instance, in the case of shipping seafood or fresh produce, maintaining a cool environment is essential to prevent spoilage. Molded EPS coolers effectively shield these products from external heat, helping to preserve their freshness.

Moreover, for pharmaceuticals that require specific temperature ranges for stability and efficacy, EPS coolers provide a reliable solution for maintaining the required conditions throughout the shipping process.

The ability of molded EPS coolers to uphold consistent temperature levels helps mitigate the risk of product damage or spoilage due to exposure to extreme heat or cold during transit.

Understanding how pivotal temperature maintenance is in packaging sheds light on the significant role that molded EPS coolers play in preserving the integrity and quality of perishable items during shipment.

Deciding if an EPS Cooler Fits Your Packaging Requirements

Picking the right cooler for shipping perishable products is crucial. As you assess whether an EPS cooler suits your needs, consider these important factors: product sensitivity and shipping distance.

Product Sensitivity

When shipping perishables, not all products are created equal. Some items, like pharmaceuticals, seafood, or fresh produce, have specific temperature needs. It’s important to evaluate the unique temperature requirements of your products and ensure that EPS coolers can effectively maintain those temperatures throughout the entire shipping process.

Shipping Distance

The duration of transportation, as well as the distance your products will travel, is another critical element to consider. EPS coolers are effective at sustaining required temperatures, but their ability to do so over long distances and extended periods is equally important.

For instance, if you’re shipping delicate desserts locally, an EPS cooler may be suitable. However, if you’re transporting fresh fish internationally, it’s essential to ensure that the EPS cooler can sufficiently sustain the required low temperatures throughout the longer transit time. In some cases, using refrigerants or gel packs alongside the EPS coolers may help extend their effectiveness over longer shipping periods.

Molded EPS Shipping Cooler Sizes

| Part No. (Cooler Only) | Part No. with Box | Interior Dimension | Exterior Dimension (Box Size) | Wall Thickness |

|---|---|---|---|---|

| NEPSP645C | NEPSP645K | 6¼ x 4⅝ x 5 | 9¼ x 7⅞ x 8⅙ | 1½ |

| NEPSP864C | NEPSP864K | 8 x 6 x 4¼ | 11 x 9 x 7¼ | 1½ |

| NEPSP867C | NEPSP867K | 8 x 6 x 7 | 11 x 9 x 10 | 1½ |

| NEPSP868C | NEPSP868K | 8 x 6 x 8 | 11 x 9 x 11 | 1½ |

| NEPSP869C | NEPSP869K | 8 x 6 x 9¼ | 11 x 9 x 12¼ | 1½ |

| NEPSP8610C | NEPSP8610K | 8¼ x 6¼ x 10½ | 11⅝ x 9⅝ x 14 | 1½ |

| NEPSP968C | NEPSP968K | 9 x 6 x 8¼ | 12⅝ x 9¼ x 11¼ | 1½ |

| NEPSP1089C | NEPSP1089K | 10⅝ x 8⅝ x 9¼ | 1313⁄16 x 1113⁄16 x 12¼ | 1½ |

| NEPSP1187C | NEPSP1187K | 11 x 8¼ x 7¼ | 14¼ x 11½ x 10¾ | 1½ |

| NEPSP1189C | NEPSP1189K | 115⁄16 x 813⁄16 x 9¼ | 14¼ x 11¾ x 12¼ | 1½ |

| NEPS12107C | NEPSP12107K | 12 x 10 x 7 | 155⁄16 x 135⁄16 x 10¼ | 1½ |

| NEPSP12109C | NEPSP12109K | 12 x 10 x 9 | 1513⁄16 x 139⁄16 x 12¼ | 1½ |

| NEPSP121213C | NEPSP121213K | 12 x 12 x 13 | 16 x 16 x 16 | 1½ |

| NEPSP13106C | NEPSP13106K | 13⅛ x 10⅛ x 63⁄16 | 16⅙ x 13⅛ x 9 | 1½ |

| NEPSP14109C | NEPSP14109K | 14⅛ x 10¼ x 9½ | 17¾ x 13⅞ x 12⅞ | 1½ |

| NEPSP141310C | NEPSP141310K | 14¼ x 13½ x 10¾ | 17¼ x 16½ x 13¾ | 1½ |

| NEPSP161210C | NEPSP161210K | 15¾ x 11¾ x 10¾ | 20 x 16 x 13⅞ | 1½ |

| NEPSP171210C | NEPSP171210K | 17 x 12 x 10 | 205⁄16 x 155⁄16 x 13 | 1½ |

| NEPSP17149C | NEPSP17149K | 17 x 14 x 9½ | 20¼ x 17¼ x 12½ | 1½ |

| NEPSP17910C | NEPSP17910K | 17½ x 9⅛ x 10⅝ | 20⅞ x 12½ x 13⅝ | 1½ |

| NEPSP171411C | NEPSP171411K | 17 x 14 x 11½ | 20¼ x 17¼ x 14½ | 1½ |

| NEPSP181211C | NEPSP181211K | 18 x 12⅝ x 11 | 21¾ x 16¼ x 14 | 1½ |

| NEPSP201313C | NEPSP201313K | 20⅜ x 13 x 1315⁄16 | 2315⁄16 x 16⅝ x 17 | 1½ |

| NEPSP201314C | NEPSP201314K | 20½ x 13¼ x 14 | 24 x 16¾ x 17 | 1½ |