As you strive to maintain the integrity of critical pharmaceutical supplies, two solutions stand out in pharmaceutical storage — Styrofoam containers and gel packs. And here at Preferred Packaging, we provide packaging like Styrofoam and gel packs for medical center pharmacies, specialty pharmacies, and test labs.

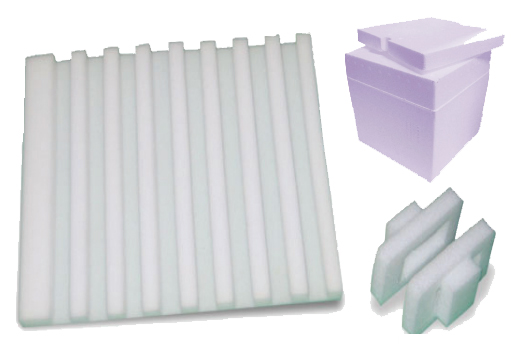

We offer a wide range of Styrofoam containers and gel packs. These products include Styrofoam containers, insulated shipping boxes, temperature controlled transport containers, and cold gel packs which are all ideal for the safe transportation of pharmaceuticals and other medical supplies, and are perfect for medical center pharmacies. We also offer custom solutions tailored to meet the specific needs of our clients, so please do not hesitate to contact us for more information.

Optimizing Styrofoam Containers for Pharmacy Use

When it comes to storing and transporting pharmaceutical products, it is crucial to ensure their integrity and efficacy. This is where styrofoam containers come into play, offering optimal solutions for pharmacy use. By implementing a few key practices, we can optimize the use of these containers and enhance the safety and freshness of medicines.

First and foremost, it is essential to select the right size and design of styrofoam containers that align with the specific needs of the pharmacy. Different medications may have varying storage requirements in terms of temperature control or insulation. By choosing containers that meet these specifications, it becomes easier to maintain an ideal environment for different types of medicines.

For instance, specialty medications that require refrigeration may require styrofoam coolers with built-in compartments for gel packs or ice packs to keep the temperature within a specific range.

Ensuring proper sealing of the styrofoam containers is another crucial factor in optimizing their use. This helps prevent any external contaminants from entering and compromising the quality of the medications. Additionally, utilizing secure closure mechanisms such as adhesive tape or zip ties can further enhance the protection and stability during transportation.

- The global cold chain logistics market was worth almost 248.4 billion U.S. dollars in 2020 and is expected to exceed 410 billion U.S. dollars by 2028.

- The Global Temperature Controlled Packaging Market is expected to grow at a CAGR of 10.02% during the forecast period 2023 – 2030

Advantages of Styrofoam Packages for Medical Center Pharmacies

Styrofoam packages offer several advantages when it comes to storing and transporting pharmaceutical products. Understanding these benefits can help pharmacy owners make informed decisions about incorporating them into their operations.

One key advantage is their excellent insulation properties. Styrofoam has a high resistance to heat transfer, which means it can effectively regulate temperature fluctuations. This is particularly crucial for medications that are sensitive to temperature variations. By using Styrofoam packages, pharmacies can ensure that the medicines remain within the desired temperature range, preserving their efficacy.

Another advantage of styrofoam packages is their lightweight nature. Compared to other packaging materials, such as glass or metal, styrofoam is much lighter, making it easier to handle and transport. This not only reduces the risk of physical strain on staff but also helps minimize shipping costs.

Styrofoam packages are also known for their durability. They are resistant to impact and provide a protective barrier against external forces. This is especially important when shipping medications over long distances or in situations where they may be subject to rough handling during transit.

Additionally, styrofoam is moisture-resistant, which helps protect medications from humidity and moisture that could potentially compromise their quality. The material acts as a barrier against water vapor and prevents condensation from forming inside the package.

By utilizing styrofoam packages, pharmacies can capitalize on these advantages to ensure the safety, freshness, and integrity of their pharmaceutical products throughout the storage and transportation process.

Utilizing Gel Packs for Pharmaceutical Packaging and Storage

When it comes to preserving the integrity and freshness of medications in a medical center pharmacy, gel packs prove to be invaluable tools. Gel packs are specially designed cooling agents that can maintain low temperatures for extended periods, making them ideal for storing temperature-sensitive medications. By utilizing gel packs, medical professionals (or healthcare assistants or other personnel) can ensure that crucial drugs remain safe and effective until they reach their intended recipients.

Gel packs work by absorbing heat from the surrounding environment when they are frozen, effectively creating a cold barrier. This makes them highly effective in maintaining a controlled temperature within pharmaceutical packaging, preventing spoilage or degradation of the medications. Additionally, gel packs are lightweight and easy to handle, allowing for convenient placement within storage containers.

Proper Gel Pack Usage for Chilling Items

Gel packs are commonly used for chilling various items, including medicines that need to be stored at specific low temperatures. When using gel packs for chilling purposes, it’s essential to follow a few guidelines to maximize their effectiveness and ensure the safety of the medication.

Firstly, it’s crucial to store the gel packs in a freezer set at the appropriate temperature. Ideally, they should be placed in a freezer set at 0°F (-18°C) or below. This ensures that the gel packs freeze completely and are at their optimal cooling capacity when needed.

Once the gel packs are frozen solid, they can be inserted into an insulated container or cooler alongside the medication that requires chilling. It’s important to place the gel packs directly next to or surrounding the medications to provide consistent cooling throughout the container. This will help maintain a stable temperature and prevent any fluctuations that could compromise the medication’s efficacy.

Additionally, it’s advisable to regularly monitor the condition of the gel packs during storage and transportation. If any gel packs show signs of leaks or damage, they should be replaced immediately to prevent contamination or inadequate cooling.

For example, imagine a medical center pharmacy where vaccines need to be transported to various clinics. By utilizing gel packs and following proper usage guidelines, the vaccines can be safely stored at the required temperature throughout the journey, ensuring their efficacy upon arrival.

Understanding the correct utilization of gel packs for chilling items in medicinal storage is crucial for maintaining the quality and safety of temperature-sensitive medications.

Guidelines on Pharmacy Packing Materials

The importance of proper pharmacy packing materials cannot be overstated. When it comes to storing and transporting medications, it is crucial to follow specific guidelines to ensure the safety and efficacy of the products. Whether you are a medical center pharmacy or a healthcare professional, adhering to these guidelines can help protect the quality and integrity of the medicines.

First and foremost, using FDA-approved packing materials is essential. The Food and Drug Administration (FDA) provides stringent regulations to ensure that packaging materials used for pharmaceutical products meet quality standards. This includes styrofoam containers and gel packs that are designed specifically for maintaining the temperature stability of medications during transportation.

For example, styrofoam containers provide excellent insulation properties, protecting medications from extreme temperature fluctuations. These containers are lightweight, durable, and provide a high level of thermal resistance. Combined with gel packs, which can be pre-conditioned to maintain a specific temperature range, they create an ideal environment for preserving medicine freshness.

Maintaining Pharmacy Medicine Quality and Safety

To ensure the quality and safety of medicines, it is essential to establish strict protocols for handling, storage, and transportation within medical center pharmacies. Here are some key considerations:

- Temperature Control: Proper temperature control is vital for many medications’ stability and effectiveness. It is important to store medicines in designated areas with appropriate climate control systems to maintain desired temperature ranges.

- Protection from Light: Some medications are light-sensitive and can degrade when exposed to direct sunlight or certain artificial lights. It is crucial to store these medicines in opaque containers or use light-blocking materials to shield them from harmful UV rays.

Utilizing styrofoam containers with built-in light blocking properties can provide an extra layer of protection against light exposure, ensuring the integrity of light-sensitive medications.

- Airtight Packaging: Medications that are susceptible to moisture or oxygen degradation should be stored in airtight packaging. This helps prevent contamination and prolongs the shelf life of the products.

Styrofoam containers with secure lids and seals, along with gel packs, can provide a tight seal that protects medications from moisture or air exposure, further maintaining their quality.

By following these guidelines on pharmacy packing materials and implementing proper storage practices, medical center pharmacies can prioritize patient safety and ensure the medicine’s freshness and efficacy.

How do you properly dispose of Styrofoam containers and gel packs after use?

Proper disposal of Styrofoam containers and gel packs after use is essential for the environment. Styrofoam can take hundreds of years to break down, contributing to pollution and harming wildlife. Gel packs contain chemicals that can contaminate water sources if not disposed of properly. To dispose of Styrofoam, it is recommended to check with your local recycling center for specific instructions. As for gel packs, many cities now offer specialized programs for their safe disposal, such as drop-off locations or mail-back services. By taking these steps, we can reduce waste and protect our planet for future generations.

What types of medication require the use of Styrofoam containers and gel packs in a pharmacy?

There are certain medications that require the use of Styrofoam containers and gel packs in a pharmacy to maintain their efficacy and stability. These include temperature-sensitive drugs like insulin, certain vaccines, biologics, and some antibiotics. The Styrofoam containers provide insulation and protection against extreme temperature fluctuations, while gel packs help maintain the desired temperature range.

Are there any eco-friendly alternatives to Styrofoam containers and gel packs for pharmacy and medication packaging?

Yes, there are eco-friendly alternatives to Styrofoam containers and gel packs for medication packaging. One such alternative is the use of biodegradable materials like plant-based plastics or compostable materials. These materials can break down naturally over time, reducing their impact on the environment. Additionally, innovative solutions like PCM (phase change material) gel packs made from renewable resources are being developed, which can provide the necessary temperature regulation for medication while being environmentally friendly.

Can the use of Styrofoam containers and gel packs affect the potency or efficacy of the medication stored within them?

Yes, the use of Styrofoam containers and gel packs can potentially affect the potency or efficacy of medication stored within them. Styrofoam containers may not provide sufficient insulation, leading to temperature fluctuations and degradation of certain medications. Gel packs, on the other hand, can pose a risk of freezing medications if not properly regulated. It is important to ensure appropriate storage conditions to maintain the effectiveness of medications.

Are there any potential health hazards associated with using Styrofoam containers and gel packs?

While Styrofoam containers and gel packs are commonly used for transporting temperature-sensitive medications, there are potential health hazards associated with them. Styrofoam contains a chemical called styrene, which can leach into the medication and pose health risks when consumed. Studies have found that exposure to styrene may lead to respiratory issues, skin irritation, and even potential reproductive and developmental problems. Additionally, gel packs can occasionally rupture or leak, causing contamination of the medication. It is crucial to consider alternative packaging options that prioritize patient safety without compromising the efficacy of the medication.

Contact Us for a Free Quote